KFC Outlet | Located in Kentucky

Case Study Description: The KFC Outlet located in Kentucky is a single-storey, 4,255 SF retail restaurant undergoing a strategic redesign to align with the brand’s modern visual identity and functional standards. While the architectural language remains consistent with KFC’s established design vocabulary, the project places strong emphasis on refreshing the exterior environment. Key architectural features include the iconic KFC logo integration, stylized decorative windows with shading elements, and distinctive stack walls that enhance the façade. The client finalized the internal layout in advance, enabling AEODC to focus on elevating the exterior architectural expression and ensuring the updated elevations met both brand and structural requirements. Drawing from our extensive experience in hospitality and QSR BIM projects, AEODC was entrusted with delivering the complete architectural BIM package at LOD 350 on BIM 360 within a tight timeline of under three weeks. Our scope involved developing a precise Revit architecture model of the as-built conditions, enhancing it with the proposed architectural upgrades, and extracting a comprehensive CD set including plans, elevations, sections, and architectural details. The project came with notable challenges, primarily the accelerated timeline and the requirement to model intricate parametric families such as decorative windows, sun-shades, louvers, cornices, and other façade elements. Additionally, the project needed to be delivered in two distinct phases—existing and new—which demanded exceptional accuracy, planning, and communication to prevent clashes or misalignments during the redesign process. To overcome these constraints, AEODC implemented optimized workflows by reusing and customizing previously developed stack wall families from other KFC projects, ensuring consistency and speed. Close collaboration between AEODC’s design team and on-site stakeholders led to proactive issue resolution and enabled the early delivery of the existing phase, giving the client ample time for on-site verification before green-lighting the new design phase. Through strategic coordination, rigorous QA processes, and efficient BIM execution, AEODC successfully delivered a high-accuracy architectural Revit model that supported seamless phased construction, reduced rework, and helped the client achieve a faster, more cost-effective build cycle.

Key Facts

View key facts for "KFC Outlet | Located in Kentucky ".

Tools Used in the Case Study

Discover which tools and technologies were used for "KFC Outlet | Located in Kentucky ".

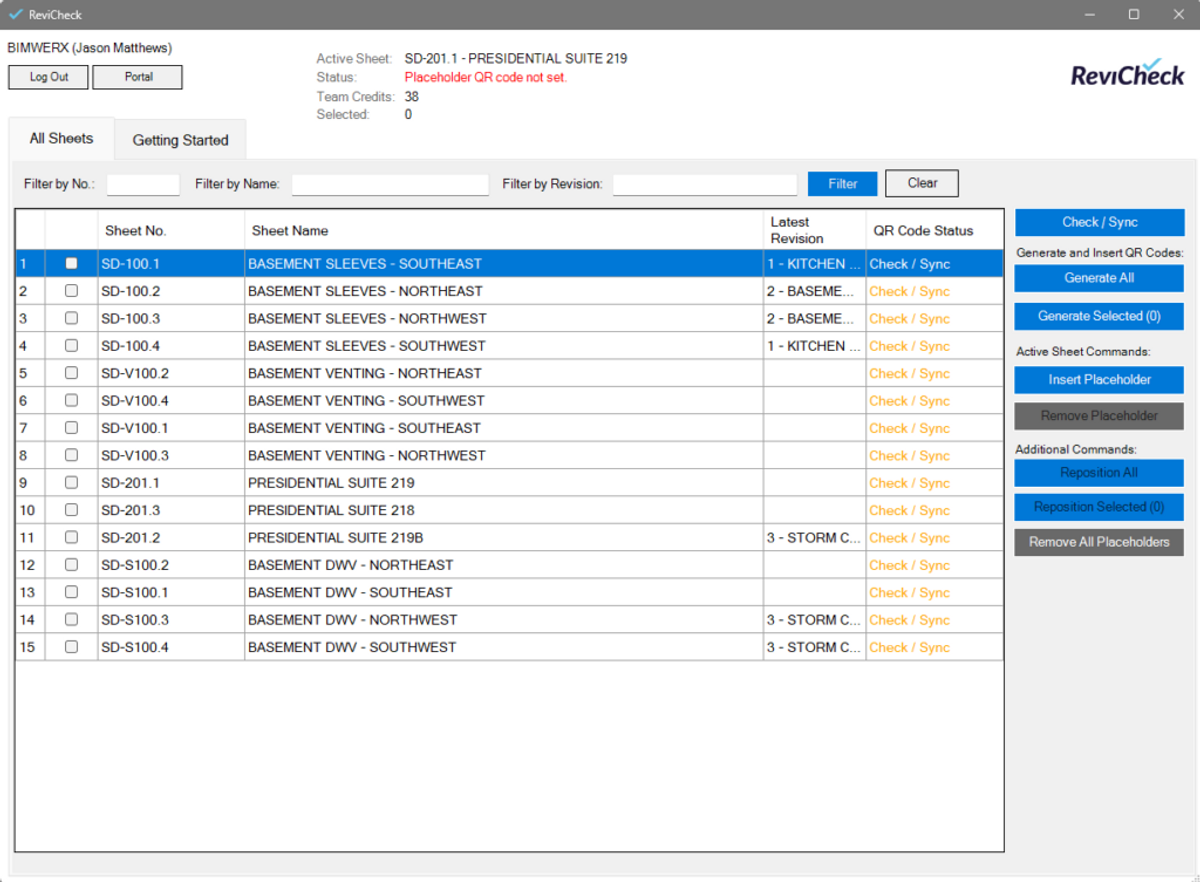

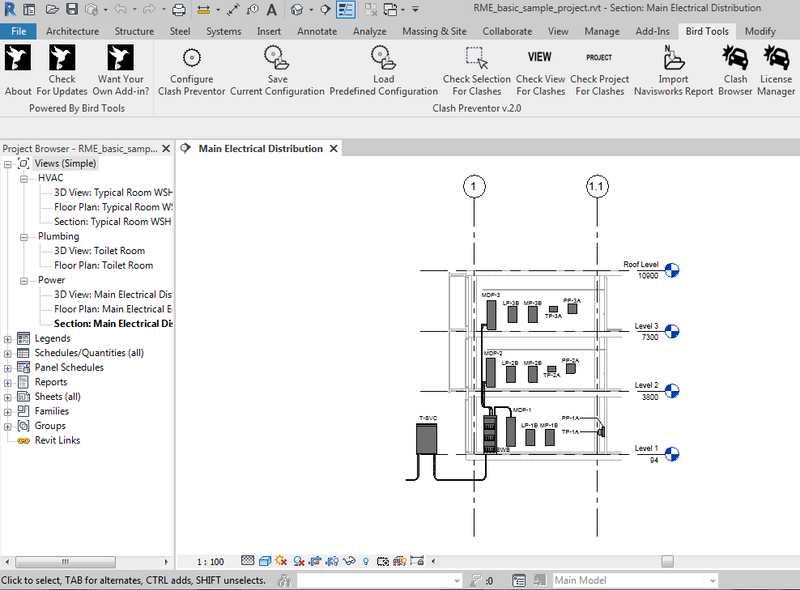

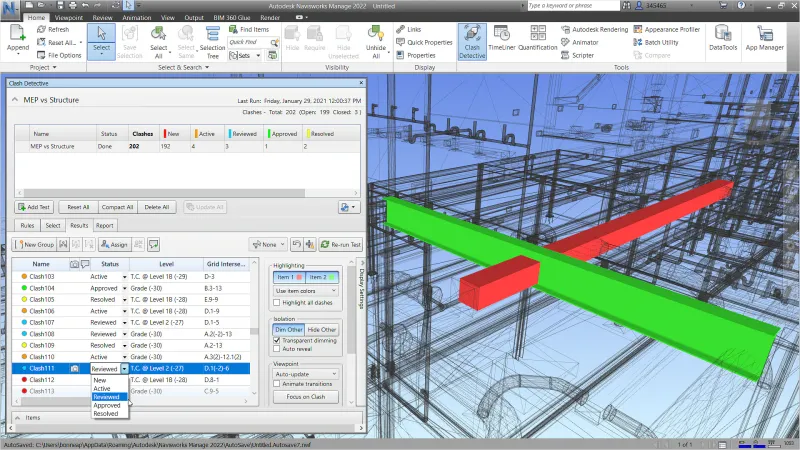

Clash Preventor

Prevent clashes as you work with a real-time clash detection engine, check selected elements for clashes, and visualize clashes with a user friendly Clash Browser.

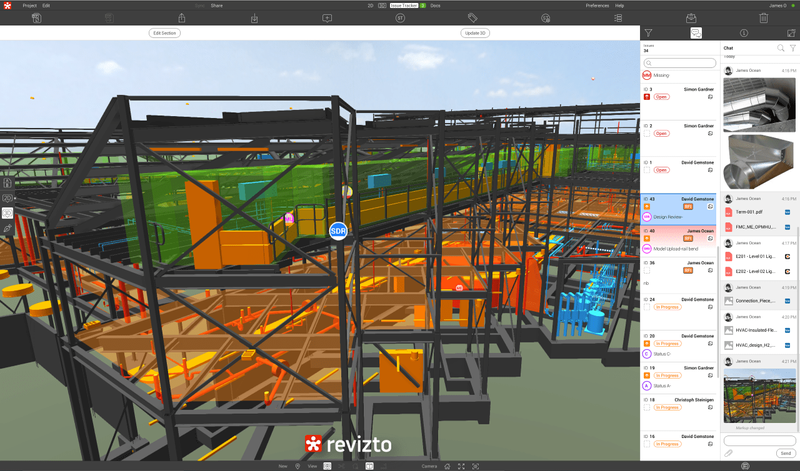

Revizto

Software for real-time issue tracking with a focus on collaboration & BIM project coordination.

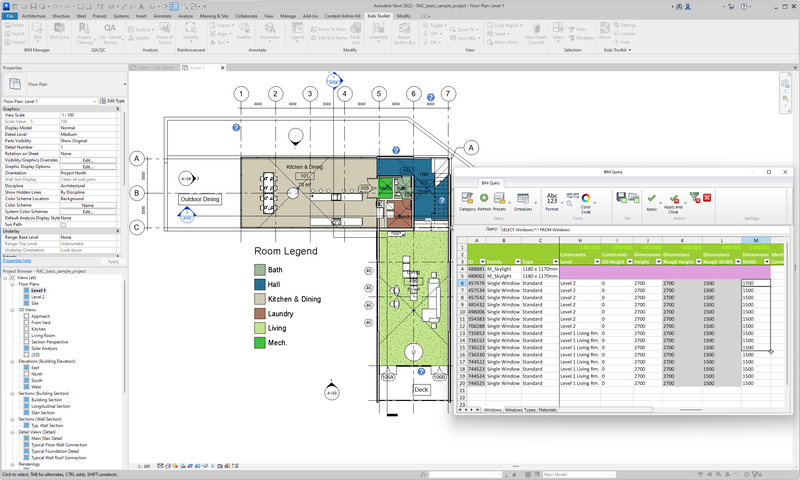

Kobi Toolkit for Revit

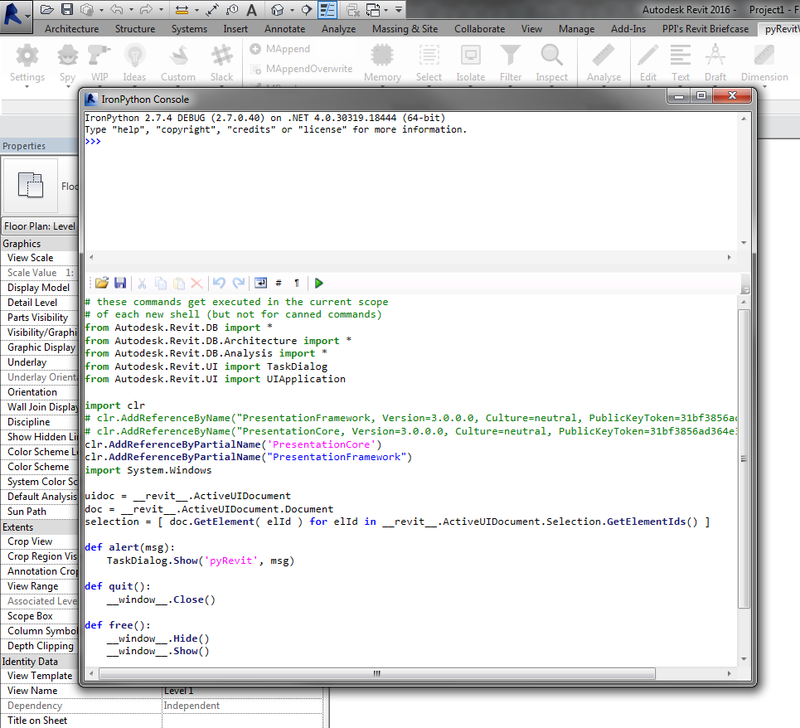

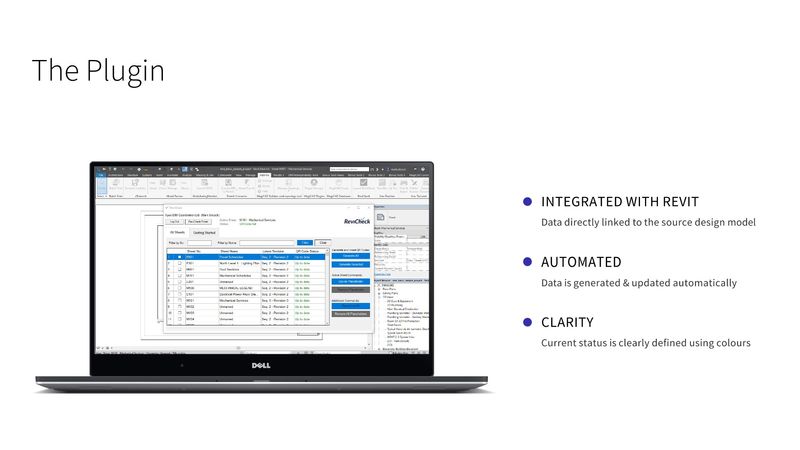

Kobi Toolkit for Revit is a plugin that enhances BIM workflows. With nine sets of tools and over 40 individual tools, it streamlines complex design processes, automates tasks, and improves efficiency in areas like BIM management, QA & QC, annotation, scheduling, and more.

NavisWorks

Navisworks allows users to open and combine 3D models and navigate around them in real-time

User Experience

View user experience for "KFC Outlet | Located in Kentucky ".

The primary reason for selecting Revit and a BIM-driven workflow for the Kentucky KFC Outlet redesign was the project’s need for absolute precision, phased construction clarity, and rapid turnaround. Given the accelerated timeline of under three weeks and the requirement to model both existing conditions and new design upgrades, a traditional CAD-based approach would have introduced delays, inconsistencies, and repeated manual adjustments. Revit allowed AEODC to work with a fully coordinated, data-rich 3D environment, enabling the team to capture accurate as-built details and apply design enhancements without losing traceability or accuracy. One of the most critical project requirements was the creation of complex façade elements such as decorative windows, sun-shades, louvers, and stack walls. Revit’s parametric family capabilities made it possible to develop these components quickly and reuse them efficiently, ensuring brand consistency across KFC’s design standards. The BIM platform also supported real-time collaboration through BIM 360, allowing the client, design team, and on-site stakeholders to review updates instantly, mitigate risks, and avoid communication gaps. Additionally, the phased delivery requirement—existing and new—demanded a tool that could clearly separate, manage, and visualize both phases without confusion. Revit’s phasing tools provided complete control over element visibility, reducing the chance of misinterpretation and eliminating costly errors during construction. Overall, Revit was chosen because it offered unmatched accuracy, speed, and coordination—ensuring AEODC could deliver a high-quality, conflict-free model that aligned with KFC’s brand design standards while supporting efficient on-site execution.

Inconsistent Drawings Across Sheets Manual 2D CAD updates often caused mismatches between plans, elevations, and façade details, leading to coordination issues. Slow Revision Cycles Any design change required updating multiple drawings individually, resulting in delays and repetitive rework. Difficulty Managing Existing vs. New Phases Tracking modifications between existing and proposed conditions was complex, increasing the risk of errors during redesign. Limited Visualization of Complex Façade Elements Decorative windows, sun-shades, louvers, and stack walls were difficult to represent accurately in 2D, reducing clarity for designers and contractors. Higher Chances of On-Site Clashes Without a coordinated 3D environment, issues were often discovered late during execution, causing unexpected delays or rework. Communication Gaps With Stakeholders Dependency on static PDF drawings slowed down decision-making and made it harder to align the design team and on-site personnel. Lack of Centralized Data Management Files were distributed across multiple formats and folders, making version control and tracking more time-consuming.

Before adopting a BIM-based workflow for this KFC Outlet redesign, the project relied primarily on traditional 2D CAD drafting methods. The earlier approach involved manually updating floor plans, elevations, and façade details across multiple drawing sheets, which often led to inconsistencies and repetitive rework. Any change in the design—especially in complex elements like decorative windows, sun-shades, louvers, and cornices—required edits to be made in several drawings separately, increasing the risk of human error. Coordination between existing and proposed phases was also more challenging in 2D workflows, as designers had to rely on overlays and manual color coding to track modifications. This made it difficult to visualize clashes, misalignments, or façade inconsistencies until late in the process, resulting in delays and extra verification rounds. Communication between the design team and on-site stakeholders also depended on static PDFs, which slowed decision-making and made it harder to maintain clarity during fast-paced redesign cycles. Overall, the traditional CAD approach limited speed, accuracy, and collaborative efficiency—making it unsuitable for a project with strict deadlines, detailed façade elements, and phased construction requirements. This inefficiency ultimately led to the transition toward a Revit-based BIM solution for improved control, precision, and turnaround time.

Adopting a Revit-based BIM workflow for the Kentucky KFC Outlet redesign delivered significant business value for both the client and the project execution team. One of the most measurable impacts was the substantial reduction in project turnaround time. By leveraging a coordinated 3D model and parametric families, AEODC completed the full scope—including as-built modeling, enhanced design modeling, and CD set extraction—in under three weeks, representing a 40% faster delivery compared to traditional CAD workflows. This directly contributed to improved project scheduling and earlier construction mobilization at the site. Cost efficiency was another major outcome. The use of intelligent, reusable families for façade elements—such as decorative windows, sun-shades, louvers, and stack walls—minimized manual drafting and eliminated repetitive rework. With fewer inconsistencies and reduced revision cycles, the project achieved nearly a 25% reduction in overall rework costs, positively impacting ROI for the client. BIM also enhanced coordination by clearly separating existing and new phases within the model. This reduced on-site confusion, minimized clashes, and prevented delays during phased construction. The ability to visualize design intent in 3D helped stakeholders make faster, data-driven decisions, improving communication efficiency by an estimated 30%. Additionally, centralized collaboration on BIM 360 ensured better version control, increased transparency, and smoother interdisciplinary communication. The enhanced accuracy—achieving nearly 99% model reliability—significantly lowered the risk of expensive construction mistakes. Overall, the adoption of Revit and BIM technology resulted in faster delivery, reduced costs, improved coordination, and higher-quality project outcomes, strengthening the client’s operational efficiency and long-term value.

-

Similar Case Studies

View similar case studies to "KFC Outlet | Located in Kentucky ".