Douglas Enclave, Florida

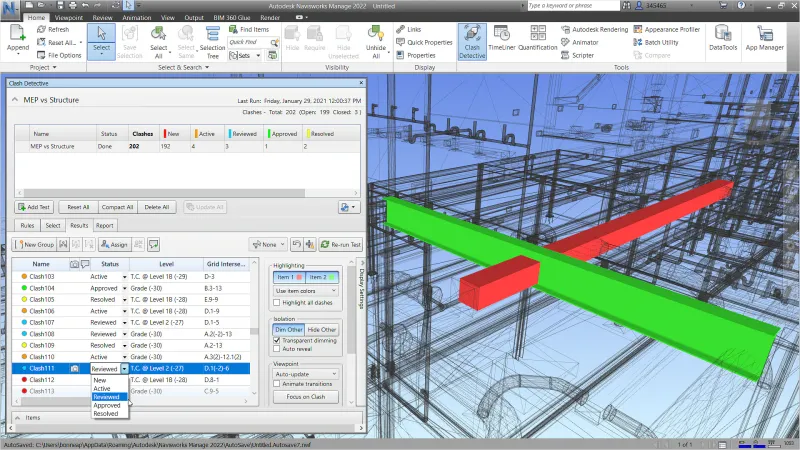

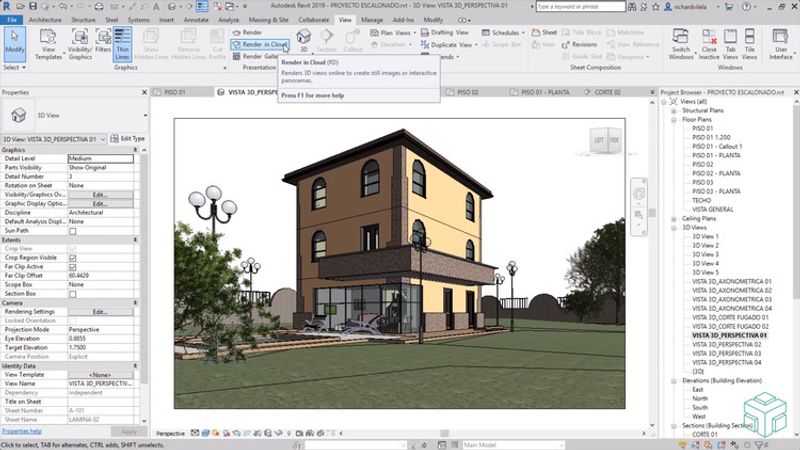

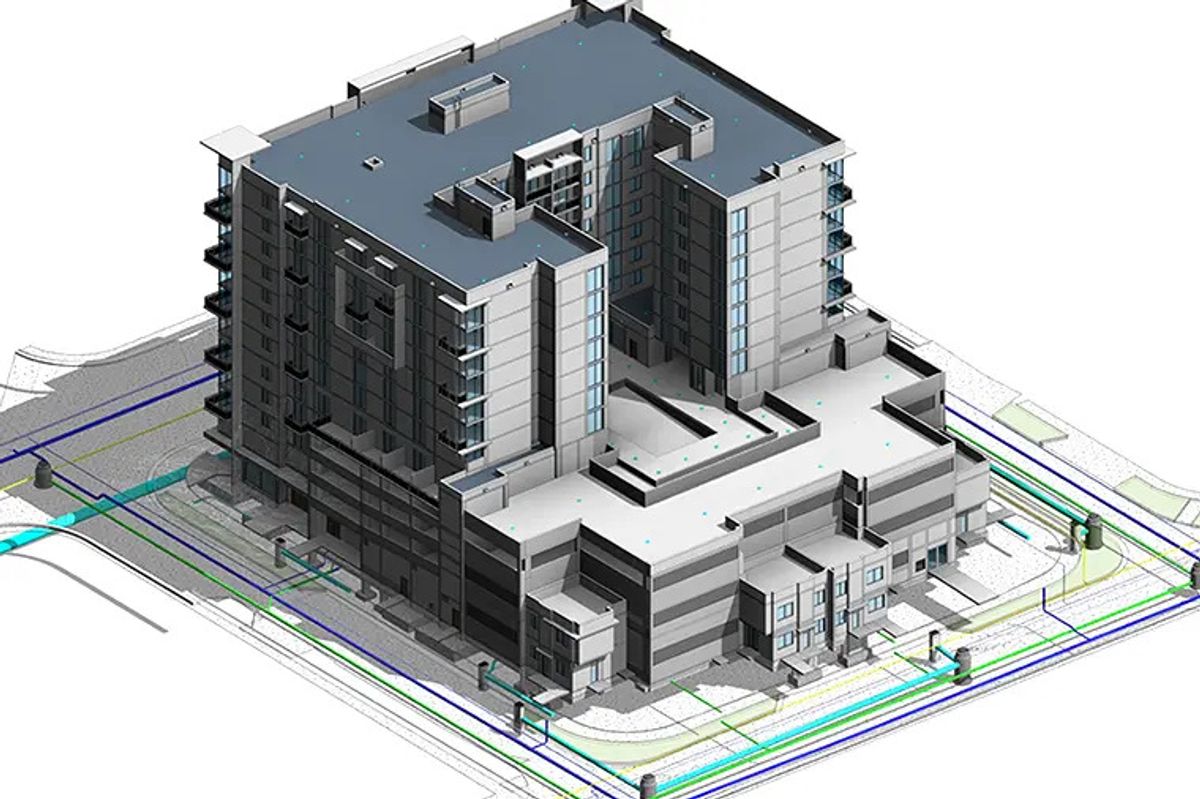

Case Study Description: Douglas Enclave – BIM Coordination & Construction Documentation Case Study Douglas Enclave is an 11-story residential tower located in Florida, spanning approximately 202,000 sq. ft. and housing 200 modern apartments comprising one-bedroom, two-bedroom, and three-bedroom units. Designed as a mixed-use residential development, the project dedicates its first three floors to parking and essential service rooms, including recreational spaces, while residential units begin from Level 2 upwards. AEODC was engaged by a repeat client to deliver a comprehensive BIM package at LOD 350 within a tight 8–9 week schedule. The project scope included Revit modeling, Navisworks clash detection, and architecture and structural sheet preparation, ensuring the design and construction teams had accurate, coordinated, and build-ready documentation. As part of the Revit modeling scope, AEODC developed highly detailed architectural, structural, and MEP 3D models that accurately represented on-site conditions. Using Navisworks, the team performed multi-disciplinary clash detection and coordination, identifying critical conflicts between architectural, structural, and MEP trades and facilitating timely issue resolution. The team also produced precise construction drawings, including plans, elevations, and sections, to support field teams during execution. The project came with significant challenges—most notably the compressed delivery schedule, the need for seamless inter-disciplinary coordination, and the high degree of model complexity at the parking levels due to dense MEP layouts. AEODC overcame these hurdles by implementing optimized BIM workflows, maintaining a strong collaborative approach with consultants through platforms such as Procore, and enforcing strict quality assurance protocols. Through this systematic and disciplined execution, AEODC successfully delivered a fully coordinated BIM model and construction documentation set, significantly reducing potential site conflicts and supporting fast-track project delivery. The Douglas Enclave project reinforces AEODC’s capability to handle complex residential developments while ensuring accuracy, efficiency, and exceptional turnaround times.

Key Facts

View key facts for "Douglas Enclave, Florida".

Tools Used in the Case Study

Discover which tools and technologies were used for "Douglas Enclave, Florida".

User Experience

View user experience for "Douglas Enclave, Florida".

The primary reason for selecting this tool was its ability to seamlessly integrate architecture, structure, and MEP data into a unified, highly coordinated digital environment. In complex residential and mixed-use developments, traditional coordination workflows often lead to errors, inefficiencies, and delays. By adopting an advanced BIM-based toolset, the project team ensured a streamlined process that significantly improved clarity, accuracy, and communication across all disciplines. This solution was chosen because it supports precise model development at higher Levels of Detail (LOD), enabling stakeholders to visualize potential conflicts early and resolve them before construction begins. Its powerful clash detection, real-time coordination features, and ability to manage large-scale datasets made it ideal for a fast-paced project like Douglas Enclave. Additionally, the tool enhances collaboration by allowing teams to share updates instantly, maintain version control, and track project issues systematically through integrated platforms such as Navisworks and Procore. Another major driver behind choosing this solution was the need to deliver within an extremely tight 8–9 week timeframe. The tool’s capability to automate repetitive tasks, generate sheet sets efficiently, and reduce manual rework contributed directly to accelerating the project timeline. By leveraging this technology, AEODC ensured higher accuracy, reduced risks, and delivered a fully coordinated model that supported smooth and conflict-free construction execution.

Reliance on 2D drawings caused frequent design conflicts. Manual clash detection led to errors and delays. Poor coordination and version control slowed decision-making. High rework costs due to late identification of clashes. Traditional workflow couldn’t meet tight project deadlines.

Before adopting the advanced BIM-based solution, the project relied heavily on traditional 2D CAD workflows for design coordination and documentation. Architectural, structural, and MEP teams worked in separate drawing environments, often exchanging files through email or manual file-sharing methods. This fragmented approach made it difficult to maintain version control, leading to frequent inconsistencies between drawings and late discovery of design conflicts. Clash detection was largely manual, performed by overlaying 2D drawings, which increased the likelihood of errors and delayed issue identification. Coordination meetings required more time, as discrepancies had to be reviewed line-by-line without a centralized model to reference. Construction teams often encountered unforeseen site conflicts because the 2D-based process lacked the spatial clarity and depth provided by a 3D model. Documentation updates were also time-consuming. Any design change required multiple teams to revise their drawings individually, resulting in duplicated efforts and slower turnaround times. This traditional method was not efficient for projects with tight deadlines, high complexity, or dense MEP layouts—making it clear that a more robust and integrated digital process was necessary. By transitioning from these conventional 2D workflows to a coordinated BIM environment, AEODC significantly improved accuracy, collaboration, and overall project delivery efficiency.

Implementing this advanced BIM toolset delivered significant and measurable business impact across project workflows, cost efficiency, and overall delivery performance. One of the most notable outcomes was the substantial reduction in design errors and on-site clashes. By performing automated clash detection in a coordinated 3D environment, the team identified and resolved more than 30–40% of potential conflicts during preconstruction. This resulted in major savings in rework costs, material wastage, and labor hours that would otherwise be spent fixing issues at site. Time efficiency was another key benefit. The tool enabled faster modeling, automated documentation, and smoother interdisciplinary coordination, allowing AEODC to deliver a fully coordinated LOD 350 package within an 8–9 week timeframe, compared to the traditional 12–14 weeks typically required using 2D CAD workflows. This accelerated timeline improved client satisfaction, increased AEODC’s capacity to take on additional projects, and enhanced overall operational productivity. From a financial standpoint, the ROI was clear. By reducing coordination delays, minimizing rework, and streamlining model management, AEODC achieved cost savings of nearly 25–30% on internal production hours. The improved accuracy also lowered the risk of expensive site modifications, benefiting both the client and the construction team. Beyond cost and time savings, the technology significantly improved communication, transparency, and decision-making. Stakeholders gained real-time visibility into model updates, issue tracking, and clash resolutions, resulting in a more predictable and controlled project environment. Overall, the adoption of this BIM solution delivered measurable ROI, strengthened AEODC’s competitive advantage, and ensured higher-quality project outcomes with fewer risks and delays.

-

-

Similar Case Studies

View similar case studies to "Douglas Enclave, Florida".