La Brea, California

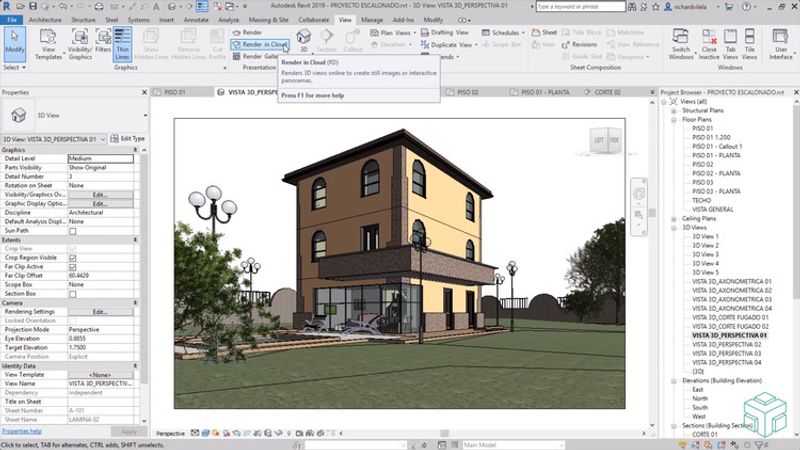

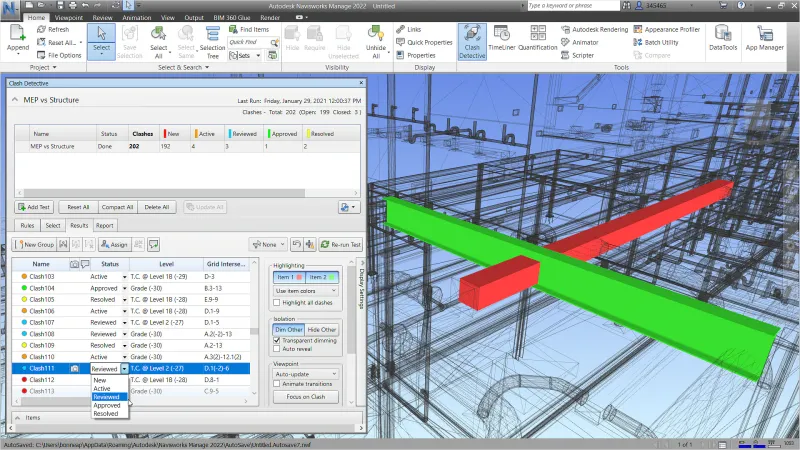

Case Study Description: La Brea is a prominent six-story residential development located in the heart of California, designed to offer modern living with high efficiency and structural sophistication. The building consists of 145 well-planned apartments, with the first floor dedicated to parking, an elegant entrance lobby, and a fully equipped business centre, creating a seamless blend of convenience and functionality for residents. Built with five stories of Type IIIA construction over one story of Type IA construction, the project spans an impressive 132,000 square feet of built-up area, reflecting a strong commitment to quality engineering and contemporary design. With extensive experience delivering BIM-enabled projects across the West Coast, AEODC was awarded this project based on proven performance and strong recommendations. The defined scope included delivering a complete LOD 300 BIM model within a fast-track timeline of 6 to 8 weeks, requiring precision, agility, and disciplined project management. The project scope involved comprehensive Revit modeling of the structure and MEP systems, multi-trade clash detection and coordination using Navisworks, and preparation of a detailed Virtual Construction Study Report outlining clashes and recommended resolutions. The project encountered challenges such as strict deadlines, complex interdisciplinary coordination, sloped site conditions, and an intricate structural layout. AEODC implemented optimized workflows, enhanced team collaboration, and stringent quality-control processes to manage these obstacles effectively. Through strategic planning and seamless coordination, AEODC successfully delivered a fully BIM-enabled model that supported smooth construction execution, reduced risks, minimized costly errors, and ensured efficient project delivery within the committed timeline.

Key Facts

View key facts for "La Brea, California".

Tools Used in the Case Study

Discover which tools and technologies were used for "La Brea, California".

User Experience

View user experience for "La Brea, California".

The primary reason for selecting this BIM-based tool and solution was the need for a highly accurate, collaborative, and time-efficient digital workflow capable of managing the project’s scale, complexity, and accelerated delivery timeline. Traditional design and coordination methods were insufficient for a multi-disciplinary development of this size, especially one involving intricate structural elements, sloped landscapes, and tightly integrated MEP systems. The BIM platform offered a centralized and intelligent modeling environment where all disciplines could work cohesively, significantly reducing miscommunication and design conflicts. The tool was chosen for its ability to deliver precise LOD 300 modeling, facilitate seamless clash detection, and support advanced visualization and simulation—all essential for anticipating issues before construction. With features like real-time coordination, automated reporting, and integrated model reviews, the solution ensured that every stakeholder had access to updated, reliable information throughout the project lifecycle. Moreover, the tool’s efficiency played a crucial role in meeting the project’s strict 6–8-week turnaround requirement. By streamlining workflows, minimizing manual tasks, and enabling faster decision-making, the BIM solution directly contributed to improved productivity and on-time delivery. Its capacity to reduce rework, enhance design quality, and optimize project costs made it the most strategic choice for ensuring successful project execution and long-term value.

Frequent Coordination Errors Manual 2D coordination caused inconsistencies between architectural, structural, and MEP drawings. High Risk of Design Clashes Without automated clash detection, many conflicts were identified only during construction, leading to costly rework. Slow Revision and Update Cycles Each discipline updated drawings independently, resulting in delays and outdated information being shared across teams. Limited Visualization Capabilities The absence of 3D models made it difficult for stakeholders to fully understand spatial layouts and design intent. Time-Consuming Manual Processes Overlaying drawings, redlining, and reviewing details manually required significant effort and slowed project progress. Poor Cross-Discipline Communication Lack of a centralized platform caused misalignment, duplicated work, and communication gaps among project teams. Inability to Predict On-Site Issues Without simulation tools, many construction challenges surfaced late, impacting timelines and budgets. Increased Risk of Rework and Delays Design conflicts and missing information often led to schedule disruptions and cost overruns.

Before adopting the BIM-enabled solution, the project relied heavily on traditional 2D CAD-based workflows for design development, coordination, and communication among various disciplines. These conventional methods primarily involved isolated drawings, manual markups, and independent updates by each design team, which often led to significant discrepancies between architecture, structure, and MEP layouts. Since the drawings were not linked or automatically updated, any design change required separate revisions across multiple files, increasing the chances of errors, omissions, and outdated information circulating within the team. Coordination during this earlier phase was largely conducted through in-person meetings, email exchanges, and manual overlay comparisons of different discipline drawings. This process was time-consuming and prone to misalignment, especially on a project with complex contours, sloped landscapes, and intricate structural details. Clash identification had to be done manually by reviewing layered drawings, which made it difficult to detect issues early and often resulted in unexpected conflicts during construction. Furthermore, the absence of a centralized digital model limited visibility for stakeholders and slowed decision-making. Construction teams depended on printed drawings, which made it challenging to visualize spatial relationships in three dimensions. The lack of real-time updates and coordinated workflows frequently caused delays, cost escalations, and increased rework on site. These limitations highlighted the urgent need for a more efficient, integrated, and technology-driven approach—ultimately leading to the adoption of BIM tools for enhanced accuracy and project control.

The adoption of BIM technology and advanced coordination tools created a significant and measurable business impact for the project, resulting in improved efficiency, reduced costs, and a strong return on investment (ROI). By transitioning from traditional 2D workflows to a centralized 3D BIM environment, the project team achieved far greater accuracy and clarity, reducing the risk of design conflicts and unexpected site issues. Automated clash detection alone eliminated up to 30–40% of rework that would typically occur during construction, directly contributing to major cost savings. The tool also played a critical role in accelerating project delivery. With streamlined workflows, integrated modeling, and real-time updates, the team was able to complete the LOD 300 deliverables within the aggressive 6–8-week timeline. This increased speed not only improved internal productivity but also supported the client’s overall project schedule, shortening decision-making cycles and reducing dependency on manual coordination methods. From a financial perspective, the use of BIM tools significantly reduced labor hours spent on rework, drawing updates, and coordination meetings. This translated into measurable savings across design and construction phases. Enhanced visualization and detailed reports further helped the client forecast risks early, preventing costly delays on site. Overall, the technology delivered a strong ROI by improving team coordination, minimizing errors, optimizing resources, and ensuring better project predictability. These efficiencies created long-term value, positioning the project for smoother execution and more reliable cost and timeline outcomes.

-

-

Similar Case Studies

View similar case studies to "La Brea, California".