Mainstreaming 3D Printed Homes

In May 2022, aec+tech hosted a panel discussion as part of their ongoing AEC-tech talk series, inviting industry leaders in Concrete 3D Printing Technology (3DCP) to discuss the trends and scope in the field. Sam Ruben from Mighty Buildings, Zachary Mannheimer from Alquist3D, and Luai Kurdi from PRINT4D talk in-depth about the nuances of the 3D printing practices in the industry, and their particular application in the area of housing. To watch and follow this and future aec+tech talks, visit our YouTube channel here.

Sam Ruben: Mighty Buildings

Sam is an innovator, entrepreneur, and co-founder of Mighty Buildings, a construction technology company based in Oakland, California. The company uses 3D printing and new composite materials and robotics to sustainably unlock production in construction. Sam has leveraged his expertise working with organizations of varying scales to help improve sustainability in the projects undertaken by his company.

He talks about the environmental impacts of the building industry that strain the planet. As a significant contributor to the climate crisis, the construction industry offers a lot of potential for carbon-cutting: both embedded and operational. He mentions the role that 3D printing could play, in being an almost zero-waste production process. Citing precedents and developments in communities across the US, Sam highlights how large-scale adoption of this technology could really unlock affordability and higher productivity in the construction process.

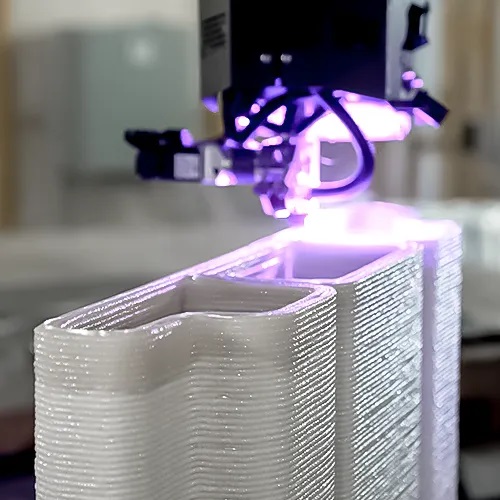

He discusses his work in developing a sophisticated building standard: the world’s first for 3D printing construction (in association with Underwriters Laboratories, UL), namely UL3401. Having laid this groundwork, Sam goes on to talk about how they organize their operations with sustainability at the core. Most of their workflows involve printing modules/components in their prefabrication space and assembling them on-site for greater quality control. They have developed a unique proprietary material that cures using UV light, enabling it to attain its strength almost instantaneously. Plus, the company uses continuous fiberglass reinforcement, rendering a strength profile that is about four times lighter and four times more thermally efficient than concrete construction. It enables them to achieve unique forms and profiles which are not possible with traditional curing methods and materials.

Further, to obtain specific finishes and textures on the concrete profiles, they mill the surface with CNC heads while the material is still soft. Ultimately, they obtain very accurate tolerances in the modules/components for on-site assembly.

We use technology to automate multiple other tasks in their workflows: the pouring of foam insulation into the cavities of the printed components; the application of spray coatings, paints, primers, and stuccos on the surfaces; and so on.

The glass fiber reinforcement adds remarkably to the tensile and flexural strength of the material, thus making it suitable for seismic zones like California, and the hurricane-prone regions of Florida.

Mighty Buildings is committed to being carbon-neutral by 2028 without the use of purchased offsets. Plus, they are investing significantly in achieving circularity in their processes, systems, and production loops; currently, they are able to recycle their grinder material and add it as a new filler, reducing the use of virgin material by at least 5 to 10 percent. Focusing on product level circularity, they aim to recycle a significant proportion of their material back into a printable form, after their usage.

Sam says that Mighty Buildings plans on expanding beyond the American market, into the Caribbean islands, Asia, and Europe. With a vision toward localizing production and printing operations across multiple regions, he says that bringing cutting-edge technology to places where they are in demand would not only solve housing problems but also bring with it new jobs and the latest in 3D Printing technology to the wider world.

Zachary Mannheimer : Alquist3D

Zack is the founder of Alquist3D, known for the first-ever 3D concrete printed affordable home in Virginia. He is also co-founder of Atlas Community Studios, a place-making and economic development group working in more than 25 states in the US. He is an opinion contributor to various reputed media houses in the country, with his works written about in the New York Times, Washington Post, and CNN, amongst others.

Zack presents a strong case where he sees Rural America as the next big place to witness a lot of innovation, stemming as solutions to the challenges that rural communities face. He cites the pandemic as a major contributor to the migration of people from urban areas towards the rural, and the suburbs. With the flexibility that modern workplace scenarios offer, it is no more a necessity to be in a major city to live, work, and play. Besides the pandemic, Zack states that climate change and economic pressure are other major reasons for people to move to rural communities.

Continuing his narrative, he talks about the issues associated with rural housing, in anticipation of the large number of people who would move out of cities. A steady increase in lumber costs in traditional buildings signals a shift to alternate technologies, where concrete 3D printing fills the gap. Zack talks about the cost savings that are possible by printing your homes, instead of building them with lumber, and claims that the expenditure could be brought down by around 30 to 50 percent in the future. In addition, in-situ concrete 3D printing reduces construction waste by around 80 percent. All homes built by Alquist3D are designed to last for 150 to 175 years and are highly capable of withstanding tornadoes and cyclones.

This technology can be adapted to make the homes be one with the built context: with only the exterior walls of the houses printed with concrete and finished with plaster + paint/stucco, the remainder is built with local technologies and materials.

Further, the exterior concrete print is compliant with all state codes with respect to structure and MEP, and they are advancing this technology to achieve varying forms and profiles, beyond rectilinear ones.

Zack talks in detail about the nuances behind their first 3D concrete printed home in Greater Williamsburg, Virginia. Being the world’s first owner-occupied 3D printed house, Alquist3D brought down the construction costs by 15 percent per sq. ft. Besides, the entire print of the exterior walls was completed in just 22 hours spread over a week and a half, again a major breakthrough for the in-situ concrete printing project. In association with Habitats For Humanity — Williamsburg, Alquist3D aims to print at least one such affordable 3D printed home a year.

In totality, Alquist3D’s commitments to community, affordability, sustainability, and technology are more than evident in their 3DCP projects. They plan on scaling up further in the near future, to cater to more such communities, providing technically sound solutions to housing issues, with the most sophisticated technology!

Luai Kurdi: PRINT4D

Luai is a young Architect and 3D concrete printing expert from Jordan. He is the founder of PRINT4D, a startup company based in Prague, Czech Republic that aims to reduce the material needed to build structures, in turn focusing on bringing down the CO2 footprint of construction. The company has been operating with a goal of zero waste in printing processes for more than three years. Luai brings his expertise to projects of scales both small and large, a noteworthy one being a fully load-bearing 3D concrete printed building in Abu Dhabi.

PRINT4D undertakes its projects in a methodical off-site printing + on-site assembly workflow. The company resolves the design of the building structure into printable modules/components; each of these components is printed using a robotic arm concrete printer without material wastage. They are then transported to the construction site for assembly. Talking about his project in Abu Dhabi, Luai has crafted most of the design and concrete print details with a highly coordinated BIM model. The model includes enough information extending to structural detail, the location and organization of MEP fixtures, etc. When the model is rationalized into modules for the print, all the detail for embedding the service fixtures get translated into form, which is directly printed to get the end output in concrete.

The project involves an entirely concrete printed envelope and internal walls, which are all load-bearing; the requirement of reinforcing steel bars is also eliminated. The printing process and assembly took up respectively 3 and 4 weeks; work progressed both on and off-site simultaneously. The use of a robotic arm printer enabled a high-precision surface finish without imperfections.

Talking about his workflow, Luai highlights the advantages of using an arm printer over its gantry crane counterpart. An indoor printing process with an arm enables greater control over the environment and thus the quality of the output print. With almost zero downtime, the prints could be executed with extremely high accuracies (+/- 0.05mm), whereas modules whose prints fail could also be reprinted without hassles. It is, therefore, possible to optimize productivity while reducing material usage and cost considerably. Luai mentions that a single person is more than sufficient to handle the off-site printing procedure entirely. Although the proprietary concrete mix that PRINT4D uses is strikingly expensive, the benefits are apparent in the quality and speed of construction, not to mention the ability to realize almost any form/geometry.

The company is committed to lowering the CO2 footprint of its projects: they don’t believe in using traditional concrete in the future. Luai talks about using structural optimization procedures to minimize profile thicknesses while still retaining structural performance. In certain cases, they were able to achieve as much as 55 percent savings on material usage, just by geometry optimization workflows. He also mentions the usage of lower cement content as well as the introduction of recycled and waste materials into the concrete mixes, as carbon-cutting measures. A combination of these methods enables them to reduce emissions to a maximum of 75%.

Luai aims to scale PRINT4D’s scope of services to construct a single assembly line for concrete printing, CNC finishing, insulation foaming, MEP integration, and on-site erection. They are also working to develop mobile print factories in shipping containers that could be transported anywhere for the printing process.

Recent Articles

Learn about the latest architecture software, engineering automation tools, & construction technologies

Blueprints AI: Generating Construction Documentation with Artificial Intelligence

In this interview, we sat down with Al Dram, CEO and co-founder of Blueprints AI, to explore how artificial intelligence is transforming construction documentation for architects. Al shares how design teams can turn prompts, sketches, and existing files into permit-ready drawing sets—and rapidly respond to city review comments using AI-driven revisions. The conversation highlights what this shift means for architecture and AEC firms struggling with time-consuming drafting workflows and growing documentation demands.

Pioneering Technical Report Management (TRM™) for AEC Firms: A Quire Deep Dive

Learn how Quire founder Kelly Stratton is reinventing technical reporting in our latest aec+tech interview, where its purpose-built TRM™ platform, WordBank-powered standardization, AI-driven Smart Search, quality control, and the Lazarus knowledge engine come together to help AEC, environmental, and CRE teams cut reporting time and errors while unlocking their institutional expertise.

Moving to the Cloud: Egnyte’s Staged Approach for Architecture Firms

As projects grow, AEC firms are rethinking data management and collaboration. This article outlines Egnyte’s six-stage Architecture Cloud Journey—a practical roadmap for moving from on-premise systems to secure, collaborative cloud environments. From assessment to continuous improvement, it shows how to streamline workflows, strengthen security, and future-proof with AI-ready infrastructure.

SaaS Founders: Are You Timing Your GTM Right?

This article was written by Frank Schuyer, who brings firsthand experience as a founder in the software and SaaS world. In this piece, he explores how founders can unlock faster growth and stronger market traction by integrating go-to-market strategy (GTM) from the very beginning of product development—rather than treating it as an afterthought.